Seeing double: IoT and digital twins

By Perle SystemsMarch 6, 2023

For many years, virtual reality (VR) was the stuff of science fiction novels and films. It made its mark in recent years in arcades across the world, filled with video game enthusiasts donning headsets to take them into another world. Now, it's being put to commercial use across nearly every industry imaginable.

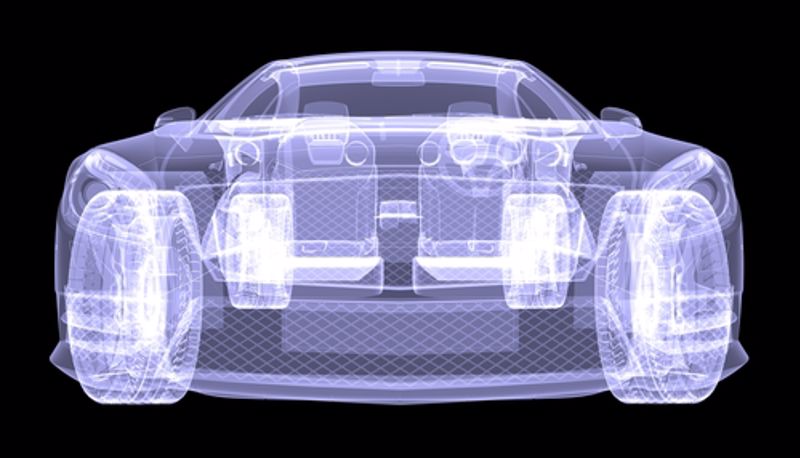

Businesses are using VR to construct theoretical models and facsimiles of real places and objects to simulate environments and how tweaking features would affect final products. These are commonly known as digital twins. And, as with almost any contemporary technology, these computer programs are intimately connected to a larger digital online network — the internet of things (IoT).

How do digital twins and IoT feed into and influence one another? And what potential applications do these connections have? Let's find out.

Spitting images

As Emeritus explains, digital twins are created by feeding real-world data into computer programs that use that information to project a 3D model of an "asset, system or environment" that can be explored using VR. This tech is primarily used by companies in industries such as automotive production, architecture and construction, manufacturing, transportation and security, although its use cases are virtually limitless.

Digital twins present a cost-effective way to determine outcomes of adjusting elements of a product or place without having to build a real model. They're also useful in terms of employee training because newly hired staff members don't have to be taken to a site to learn the ropes: They can simply put on their goggles and instantly be immersed in an exact replica of the environment in which they'll eventually work.

How IoT fits into the 3D picture

Programs like those that generate digital twins are smart, and they rely on equally smart technologies to power them. As previously mentioned, digital twins often coincide with VR, but they also utilize machine learning (ML), artificial intelligence (AI), data analytics and, notably, IoT. A digital twin's success hinges on its ability to manipulate information collected and transmitted by smart sensors — that is, IoT devices.

More importantly, the data that IoT tech gathers is fed to the program generating the digital twin in real-time. This means that it can respond to any changes either made to the digital twin itself, or to the environment from which data is sourced. According to PTC, IoT is the bridge between the physical and digital worlds.

Per Network World, this allows engineers, scientists, architects and the like to use the digital twin to optimize and enhance processes and products to achieve peak performance. Conversely, by using IoT, digital twins can also predict failure, which allows people working on the project to make crucial decisions, repairs and alterations well ahead of time.

Connecting digital twins to IoT is vital because the information that those sensors and devices fetch is far more comprehensive and accurate than what people could manually feed the program creating the digital twin. After all, we're only human and we make mistakes that automated tech doesn't. IoT can fill in gaps that people don't even know exist. Hand in hand, digital twins and IoT will revolutionize product and business development.

Perle is proud to be a pioneer

At Perle Systems, we offer an extensive selection of IoT hardware and software that can be used in next to all contexts and industries to help take your business to new frontiers.