IoT and the Fourth Industrial Revolution

By Max BurkhalterJanuary 24, 2022

The "Fourth Industrial Revolution" – as industry pundits have called it – is upon us – and the future is digital. With communications, technology and AI systems evolving, breakthroughs are occurring at exponential rates, according to data published by the Association for Project Management.

The third industrial revolution began in the 1950s with the rise of semiconductors, as well as both mainframe and personal computing. The fourth industrial revolution brings the concept of cyber-physical systems – the merging capabilities of man and machine – to a wealth of industries.

Often described as 'anything that connects to the internet,' the internet of things (IoT) is powering this exponential leap in technological advancement, dubbed 'Industry 4.0,' or '4IR.' Let's take a look at four impacts these advancements will have in 2022 and beyond.

Like GPS, but better

The city of Aarhus, Denmark is launching Testbed in Aarhus for Precision Positioning and Autonomous Systems (TAPAS), a real-time kinematic (RTK) positioning system. Information is transmitted between a network of 11 reference stations, placed around Aarhus in 10 km distances. Data is processed, estimated and transmitted to end-users on the internet at blistering speeds. Currently accessible for free to end users in the area as part of a research and development project, TAPAS champions functionality that will result in increased visibility in the most challenging, dense urban centers.

IIoT in the manufacturing space – proactive vs. reactive repair

The industrial internet of things (IIoT) boasts a significant boon to the manufacturing industry by establishing predictive maintenance thresholds. Predicting equipment damage and forecasting repair needs before a malfunction, productivity is increased and downtimes associated with equipment failure can be reduced.

According to data compiled by NASA and the US Navy, preventative maintenance schedules run on cycles related to equipment age and account for as little as 18 percent of all equipment failures. Predictive maintenance technologies, however, may help account for the estimated 82 percent random accident threshold typically associated with significant malfunction. ARC Advisory Group data highlights the dramatic impact predictive maintenance applications will have upon the industry by highlighting inefficiencies associated with a time-based, routine maintenance schedule.

Cyber-Physical Systems (CPS) and the effect on the industry

Sometimes known as cyber manufacturing, CPS refers to an industry 4.0-powered manufacturing environment in which real-time data collection, interpretation and analysis drive productivity. An engineering discipline focused on technology, CPS has roots in mathematical abstraction, as outlined in a concept map coordinated by the University of California, Berkeley. Programmed to control and monitor physical processes that, in turn, impact computation and feedback loops, CPS affect devices with functions typically not associated with computation. Cars, medical equipment and tools all have potential advancement outcomes as a result of cyber-physical systems integration.

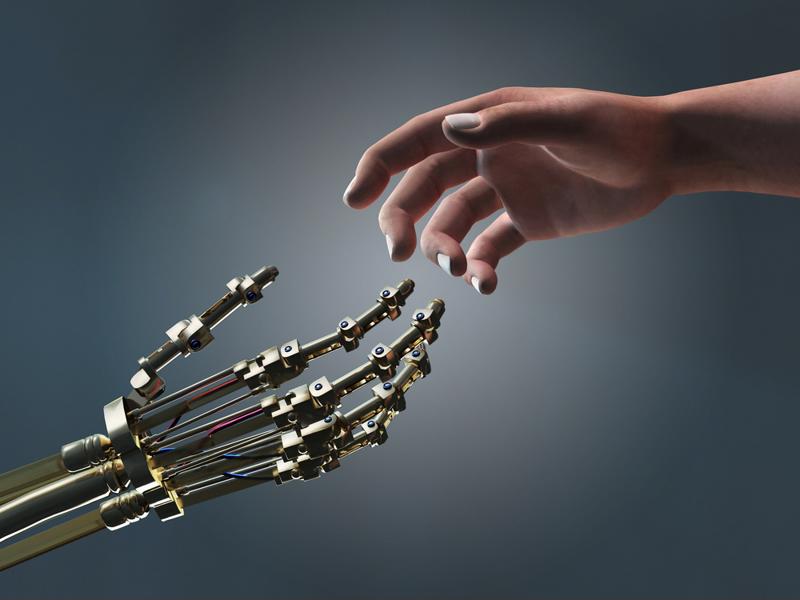

Collaborating with robots

Also known as 'cobots,' collaborative robotics furthers the integration of man and machine in regards to manufacturing outcomes. Designed to work seamlessly with operating systems, fellow machinery and humans, this particular branch of robotics works in close proximity to collaborators. Traditionally separated to ensure both productivity and safety, industry 4.0 cobots are lightweight, moveable and possess processing capabilities far superior to their predecessors.

Forbes outlined applications in the healthcare space and deemed cobots the hardware version of the augmented intelligence previously confined to software. This collaboration – described as maximizing the best of human capability with the best in AI-assisted intelligence – is a notable breakthrough of the fourth industrial revolution.

4.0 and beyond

With advancements in manufacturing, data processing, robotics and more, the internet of things is having a dramatic effect on the way industry 4.0 continues to evolve in 2022 and beyond.

Read more about the ways Perle is influencing 4IR on our Industrial Automation page, and explore how Perle can support your business with the latest IoT ready routers, DIN Rail Power Suppliers and more.