Aker Solutions choose Perle Device Servers for high data throughput rates

IOLAN Device Servers enable critical communication between topside and subsea equipment.

Billions of people worldwide depend on the oil & gas extracted below the sea for mobility, comfort and business. The infrastructure behind this extraction is vast. The environment is remote. The conditions are extreme. No industry has more demanding requirements for safety and reliability than oil and gas production.

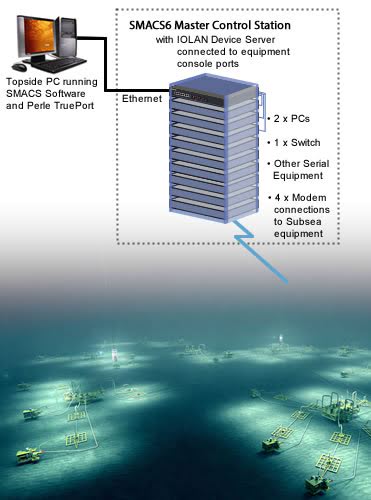

Visible to the world is the oil platform but, what lies beneath is a complex infrastructure of pipelines, sensors, probes and robotic vehicles. For efficient, safe and reliable drilling and extraction, there must be seamless communication between the platform and the underwater infrastructure. It is imperative that these systems operate flawlessly, as outages cost in excess of $1 million per day. Therefore, on every platform, you will find a Master Control Station (MCS) dedicated to the control and transmission of data between topside and subsea equipment.

Aker Solutions is a global provider of products, systems and services to the oil and gas industry. They have over 50 years of experience and specialize in complete subsea production systems. As a supplier to Britannia Operator Limited, a joint venture between ConocoPhillips and Chevron, Aker was conducting a system upgrade on the Britannia Satellites Platform.

The oil & gas industry relies heavily on SCADA systems, PLCs and other industrial equipment that have serial data communication ports. However, as TCP/IP is now the defacto standard in industrial environments, a method to reliably connect the serial devices to Ethernet is required

A project was initiated to replace the iConTM MCS with the SMACS6 MCS. The SMACS6 Master Control Station provides complete control and monitoring of subsea installed equipment and surface electrical and hydraulic power units

In the design phase of the SMAC6 MCS, Aker Solutions, needed to source a Serial Device Server that would provide critical serial to Ethernet connectivity. They needed a Device Server that would interface with the SMACS software, modems, Ethernet switches, other 3rd party serial devices and communicate with subsea modules. The amount of data throughput would be substantial.

Rigorous lab testing was carried out with Device Servers from three leading manufacturers, including Perle Systems. The units were subjected to three main areas of testing.

- COM Re-director Utility capable of interfacing with SMACS software

- Uptime without resets

- Data throughput

It was the data throughput and system stability that raised Perle above the rest of the pack. During testing, an error rate of around 1 in every 10,000 messages was required in order to pass the test – after more than 1 million messages without errors, the Perle Device Server was the clear winner.

After an extended soak test – 17 hours and counting –the Perle IOLAN not only smashed the comms stats from the competitors, but it exceeded Aker’s expectations by outperforming with no lag time or errors.

The new SMACS6 MCS with integrated IOLAN Serial Device Servers is currently installed and operating seamlessly on the Britannia Satellites platform.

The Britannia Satellites platform, situated 210km northeast of Aberdeen on the UK continental shelf operates in the Britannia Field, extracting oil and gas. It receives gas condensate and oil from nearby oilfields, which flow through the main platform for further processing, compressions and export. The annual throughput of oil exceeds 20 million barrels.

About Aker Solutions www.akersolutions.com

Aker Solutions is a global provider of products, systems and services to the oil and gas industry. Its engineering, design and technology bring discoveries into production and maximize recovery. The company employs approximately 17,000 people in about 20 countries.