Burns Industries use Perle Ethernet Extenders to facilitate efficient delivery of heating oil

They needed to stop sending delivery trucks out on long journeys to rural customers whose tanks were still more than half full.

For heat, many rural households in the Northeast USA rely on propane gas and heating oil deliveries. To optimise the schedule of delivery truck rolls for a local energy supplier, Burns Industries was asked to design a system that would give the energy supplier information about the customers remaining tank capacity.

Delivery trucks were being sent out on long journeys to customers whose tanks were more than half full

, explains Joseph Griffiths, Engineer at Burns Industries. Frequent truck rolls were proving to be inefficient and expensive

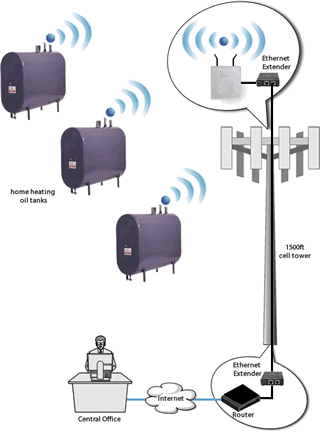

Burns Industries designed a state-of-the-art system, where each cylinder and oil tank within a trial area was fitted with a wireless transmitter that sends daily updates about its capacity status over the cellular network to the nearest cell tower. Upon receipt and collation of the data, an accurate and efficient delivery schedule could be devised.

The customer is not left waiting for a delivery after running out of heating fuel, and the energy provider is not sending out delivery trucks to customers unnecessarily,” comments Griffiths. “It is a win-win situation.

The infrastructure behind this operation required the installation of a cell tower network. Each cell tower has an enclosure mounted to the top and bottom, connected by a custom tower cable. The top enclosure contains a cellular transmitter which receives tank status data. Ethernet is used to transmit that data to the bottom of the tower where it is processed and routed to the energy supplier. However, as some of the cell towers were taller than 1500ft, and Ethernet data transmission is limited to 328 ft, Griffiths required a way to transmit the data down the towers.

Perle Ethernet Extenders, capable of extending Ethernet up to 10,000ft, were installed at the top and bottom of the taller towers to bridge the transmission distances with ease. Burns Industries selected Industrial Temperature models as they would be the most reliable during temperature fluctuations at these outdoor sites.

It was important that we could rely on the quality of the products at the top of the towers

, comments Griffiths. Scaling up and swapping out some hardware is a complicated procedure that we don’t want to do very often.

About Burns Industries: www.burnsindustries.com

Burns Industries has been a flexible and reliable partner for companies with the need for contract manufacturing In the United States, as well as offshore since 1995. Our goal is a satisfied customer. When we partner with your organization, whether to build a prototype or full production, you can trust us to deliver on time, on budget and per your specifications. The bottom line is that we ensure your products are delivered 100% to meet your requirements with the highest quality standards.